About

Who we are

Heli-One offers a complete service to support your mission readiness and maximise availability. Our deep expertise and experience in all dimensions enable us to meet whatever your requirement. We invest in our customer relationships and in our customer service culture. We aim to always listen and adapt, so that we continuously improve your experience with us. Turnaround times for you are a priority for us, along with accurate timings and service cost. We want to be your reliable partner. Supporting your success.

Our Global Reach

We support helicopters from an extensive range of original equipment manufacturers and have global reach. We welcome helicopters at our three service centres in: Stavanger, Norway; Richmond, Canada; and Rzeszow, Poland. And we also dispatch our experts to customer sites, through our in-service support offer.

Key Facts

Helicopter operator customers

Employees across 30 Countries

Global service centres

Our Leadership Team

Heli-One has strong leadership and an ambitious growth strategy for the coming years. Collaborating and knowledge-sharing with CHC Helicopter’s flying operations, we aim to enrich our customer offering and expand into more markets. Bringing our excellence in helicopter maintenance to more customers.

Our locations

HEAD OFFICE

222 W. Las Colinas Blvd

Suite 2050, North Tower

Irving, TX 75039

HELI-ONE NORWAY AS

PO Box 204

N-4097

Sola, Norway

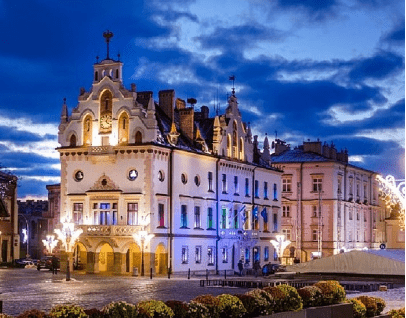

HELI-ONE POLAND

Rzeszow Airport

36-002 Jasionka 947

Poland

HELI-ONE CANADA, Richmond & Delta

4740 Agar Drive

Richmond, BC, Canada

V7B 1A3

8500 River Road

Delta, BC, Canada

V4G 1B5