Solutions

What we do

Heli-One has a single purpose – to ensure our customers are mission ready. We combine tailored solutions with an expert team to optimise your helicopter performance and availability, maximising its value over its lifetime.

Solutions

Aircraft Maintenance

We meet the highest quality and regulatory standards for both commercial and military platforms. Our maintenance facilities are Part 145 certified and our in-house quality management system is built upon the internationally recognised standards ISO 9001, AQAP 2110 and AS 9110, in addition to being OEM-authorised services and repair centres.

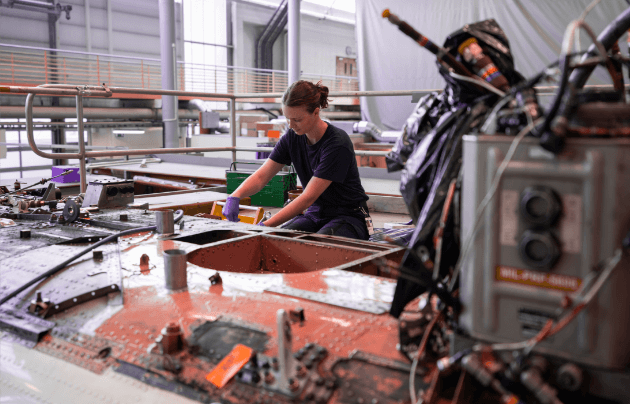

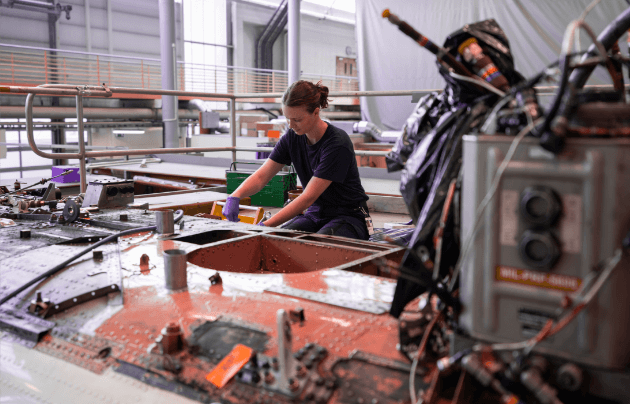

Base Maintenance

We provide base maintenance for aircraft from around the world at our facilities in Canada, Norway and Poland. These state-of-the-art facilities, provide more than 250 types of major inspection across 18 bays and over 430,000 sq ft.

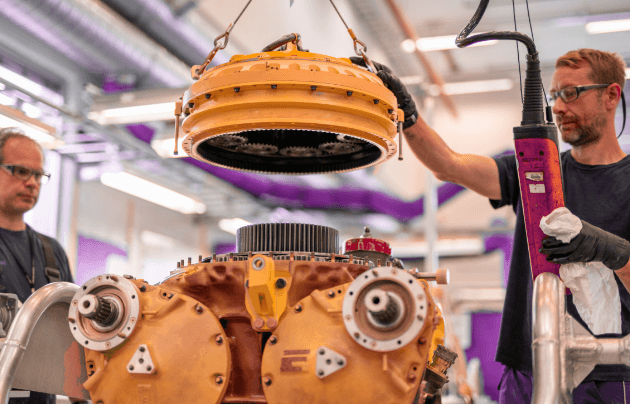

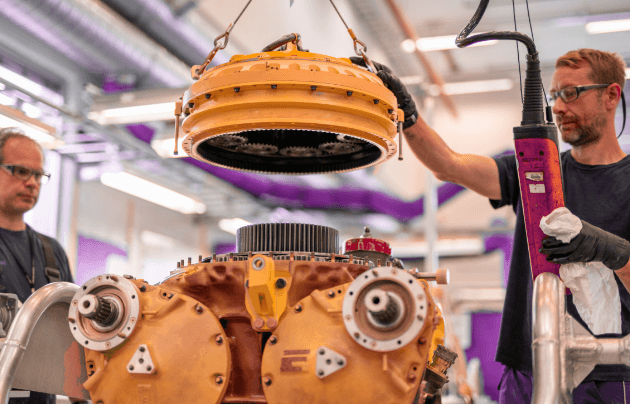

Component & Engine Repair

Our expert component teams operate in state in of the art facilities to deliver high-quality, repair, overhaul, modification and testing on a wide variety of components and OEM authorized engine services.

CAMO & Embedded Maintenance

CAMO provides comprehensive solutions for continuous airworthiness management, minimizing fleet operating costs and maintaining the highest safety standards.

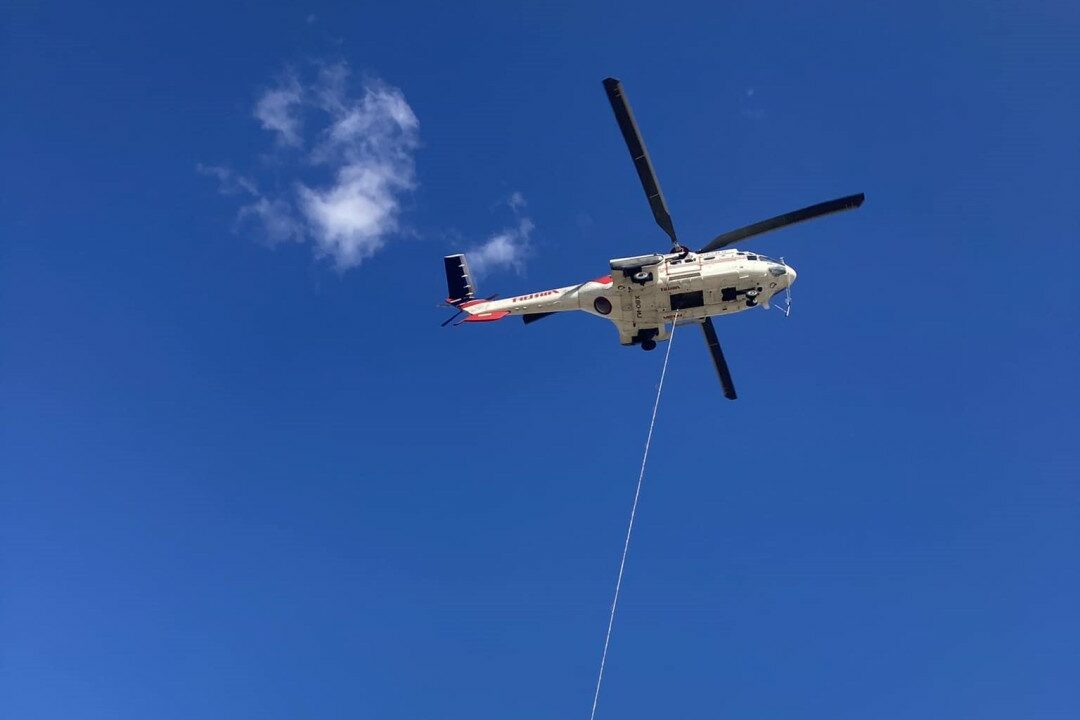

Our embedded services – including mobile repair teams and line maintenance – are designed with customers in mind.

We keep in-service aircraft flying in some of the world’s harshest environments.

Engineering, Design & Modification

Our expert team offers Part 21 certified design services to both government and civilian customers. We combine our design capabilities with technical and engineering skills to develop solutions that meet our customers vertical aviation needs.

Download our design catalogue as a searchable PDF.

Parts Supply

Our customer support teams offer an exchange service with pool and ‘Build-to-Spec’ options to eliminate repair and overhaul turnaround times and minimizes aircraft downtime.

Expertise

Heli-One mechanics and engineers have a real passion for helicopters. For them, every helicopter is personal. Their deep expertise and experience in an extensive range of helicopters define the industry standard.

We invest in future talent to ensure the Heli-One expertise of the future. We provide apprenticeships at each of our three service centres.